Updated: 2023-09-20

Recently, two professors, Xue Yunfei, from the School of Materials Science and Engineering at Beijing Institute of Technology (BIT), and Li Xiaoyan, from the School of Aeronautics and Astronautics at Tsinghua University, collaborated on a research paper titled "Dynamic deformation behaviors and mechanisms of CoCrFeNi high-entropy alloys". The paper was published in Acta Materialia, a top journal in the field of metallic materials. The co-authors of the paper include Dr. Cao Tangqing from BIT and Dr. Zhang Qian from Tsinghua. Profs. Xue and Li are the co-corresponding authors of the paper.

The research team studied the deformation behavior of CoCrFeNi high-entropy alloys (HEAs) with a face-centered cubic (FCC) structure. Their study covered a wide range of strain rates, spanning eight orders of magnitude (5.0×10-5 /s to 6.5×103 /s), through quasi-static and dynamic mechanical tests.

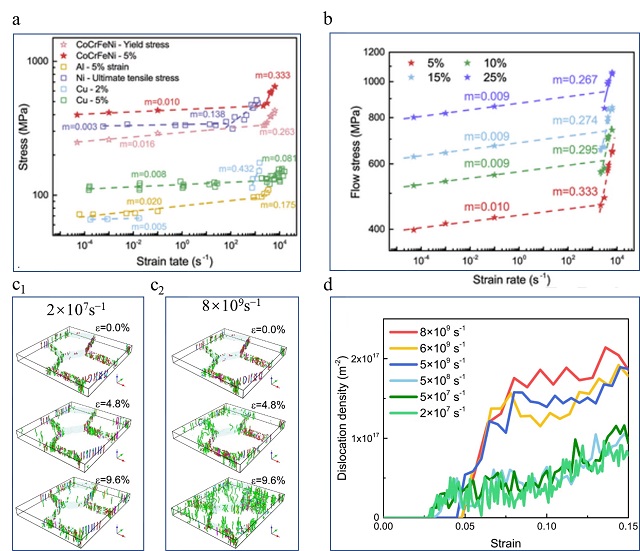

There were two key findings: (i) The CoCrFeNi HEA displayed a significantly higher strain-hardening capability when compared to conventional FCC metals. (ii) The shift in the strain-rate sensitivity coefficient corresponded to a notably lower critical strain rate than that observed in traditional FCC metals.

Motivated by these discoveries, the research team employed a combination of experimental characterization and large-scale molecular dynamic simulations to delve into the microscopic mechanism of the dynamic mechanical response of typical FCC-phase HEAs.

The research team found that the strain rate effect of FCC high entropy alloys (HEAs) is mainly due to the continuous lattice distortion effect. The resistance to dislocation motion in HEAs is affected by the short-range stress field caused by this lattice distortion, which only acts within a few tens of atoms. As a result, this resistance is highly influenced by thermal activation and shows a clear rate correlation.

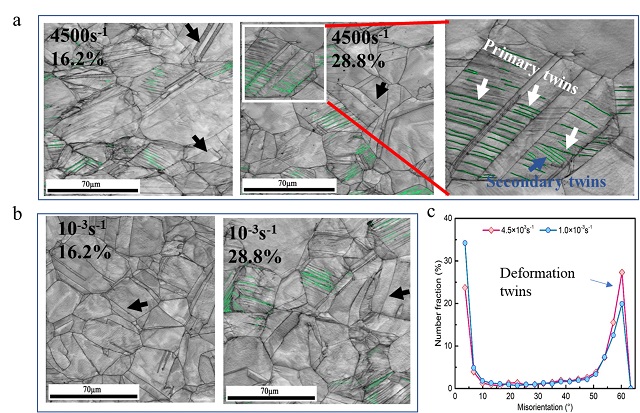

Additionally, the continuous lattice distortion in HEAs leads to a high phonon drag effect. This effect causes the high entropy alloy to approach the upper limit of dislocation velocity earlier during deformation at high strain rates. This, in turn, causes dislocations to proliferate rapidly, resulting in the strain-rate sensitive coefficient of the sudden increase in the phenomenon to shift to a low strain rate. The significant strain-rate reinforcement of the FCC HEAs and the characteristics of the sudden increase to a much lower strain rate can take place, so that it is more likely to reach the threshold of twisted-crystal-activated stress during loading at a high strain rate, inducing a large number of deformed nanotwins and generating a dynamic Hall-Peach effect, resulting in the significant enhancement of work hardening capacity.

The study sheds light on the plastic deformation mechanisms of HEAs under dynamic loading, providing guidance for the design and fabrication of HEAs with excellent dynamic mechanical properties.

https://www.sciencedirect.com/science/article/abs/pii/S1359645423006730

(DOI: 10.1016/j.actamat.2023.119343)

Fig. 1. (a-b) Variations in yield stress and flow stress at a strain rate of 5%; variations in flow stresses of different strains and strain rate; (c-d) dislocation evolution during deformation of the simulated sample at different strain rates.

Fig. 2. Microstructures of CoCrFeNi HEAs after deformation at different strain rates. Under dynamic loading, deformation twins of CoCrFeNi HEA occur earlier, more and even secondary twins are formed: (a) deformed structure at 4500s-1 strain rate; (b) deformed structure at 10-3s-1 strain rate; (c) the difference in distribution statistics show that the twin content is higher under dynamic conditions.