Updated: 2025-05-22

Professor Chen Haosen's team at the Advanced Structural Technology Institute, Beijing Institute of Technology (BIT), published a research paper in the journal Nature on May 14, presenting a new perspective on "intelligent batteries".

The article, titled Wireless transmission of internal hazard signals in Li-ion batteries, explores the wireless transmission of internal hazard signals in Li-ion batteries.

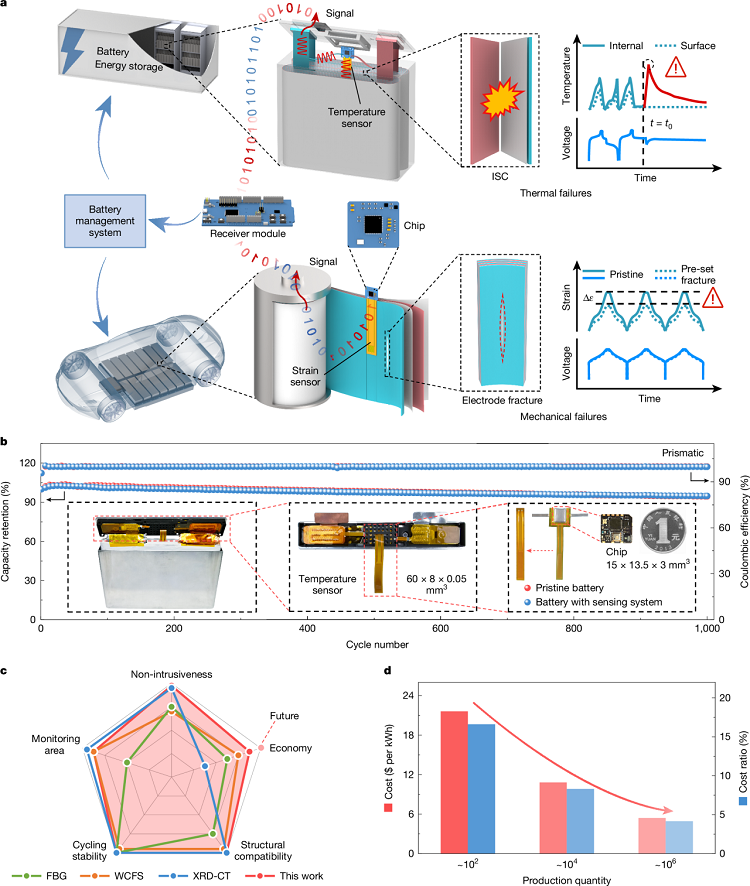

Timely acquisition of internal signals for early fault diagnosis and warning is crucial for the safe operation of commercial batteries. Therefore, the team has independently developed a non-destructive implantable intelligent sensing system for battery cells, which can measure and wirelessly transmit internal signals accurately, stably, and over the long term, significantly improving the safety and long-term operational stability of batteries.

In recent years, there has been rapid development in energy battery technology, but safety issues are becoming increasingly prominent. Professor Chen's team has spent more than a decade on interdisciplinary research and has proposed four ideas: corrosion resistance sensing (accurate measurement); non-destructive implantation (successfully embedded); cross-screen transmission (efficient transmission); and intelligent early warning (effective utilization).

The non-destructive implantable intelligent sensing system for battery cells

Based on the ideas, the team has designed a miniaturized, low-power implantable sensing system that can accurately sense and wirelessly transmit temperature and strain signals inside lithium-ion batteries. This implantable sensing system exhibits ultra-low power consumption (0.068‰) in commercial 100 Ah prismatic lithium iron phosphate batteries. Prismatic batteries integrated with this sensing system show high stability over 1,000 cycles, with a capacity retention rate of 93.74 percent, nearly equivalent to batteries without the integrated system in terms of cycle stability.

By combining a predictive model constructed on the basis of a backpropagation neural network and internal strain signals, the system achieves the localization of electrode fracture positions. Through the use of an implanted temperature sensing system and internal short-circuit trigger technology, early diagnosis of thermal failures inside prismatic lithium-ion batteries is realized. This implantable sensing system can identify abnormal temperature and strain signals inside the battery at an early stage, thereby enhancing the safety of lithium-ion batteries.

This work has promoted the practical application of intelligent sensing in energy storage stations and electric vehicles, accelerating the intrinsic safety process of energy batteries. It has driven the industry towards a safer and more sustainable future, contributing essential safety measures to China's smart solutions for global new energy development and realization of the "dual-carbon" goals.